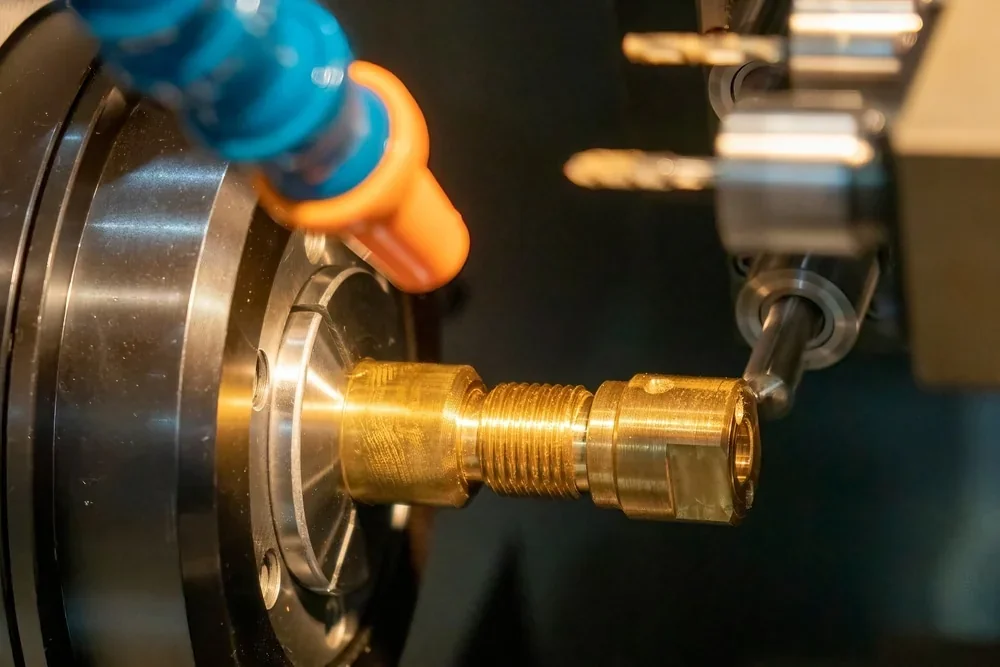

Top Prototype‘s Swiss machining services provide a highly efficient and precise solution for manufacturing large quantities of precision shaft parts. These services are widely utilized across various industries, including medical equipment, optical equipment, aerospace components, and more. With advanced CNC Swiss lathe machining, high-quality parts can be produced with exceptional accuracy and consistency.

Applications of Precision Shaft Parts

Precision shaft parts produced through Top Prototype’s precision Swiss machining services play a crucial role in multiple industries. In the medical field, these components are used in surgical instruments and diagnostic devices, ensuring reliability and precision. Optical equipment manufacturers rely on these parts for lenses and high-precision focusing mechanisms. Additionally, aerospace components require stringent tolerances, which Swiss machining can efficiently achieve. Other applications include timers, needles, and various industrial shafts.

Advantages of CNC Swiss Lathe Machining

CNC Swiss lathe machining offers several benefits, making it the preferred choice for high-precision manufacturing. The technology enables the production of intricate parts with tight tolerances, reducing errors and enhancing product quality. Additionally, Top Prototype’s precision Swiss machining services provide cost-effective mass production capabilities, allowing businesses to manufacture large quantities efficiently. The automated process also minimizes material waste, leading to greater sustainability and cost savings.

Conclusion

Top Prototype’s Swiss machining services provide an essential solution for manufacturing precision shaft parts across various industries. With applications in medical equipment, optical devices, aerospace components, and more, these services ensure high-quality and efficient production. The advantages of CNC Swiss lathe machining, including accuracy, cost-effectiveness, and sustainability, make it an ideal choice for businesses seeking a reliable service for Swiss machining.